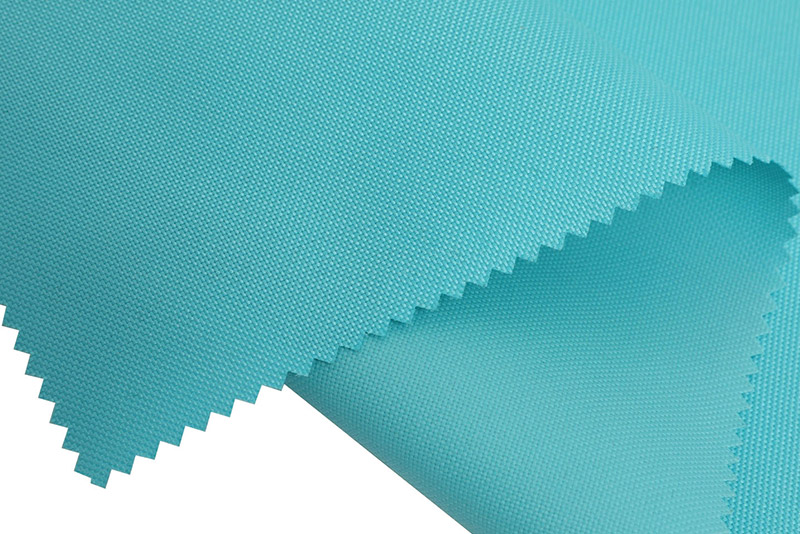

Polyester fiber, commonly known as "polyester". It is a synthetic fiber obtained by spinning polyester obtained by polycondensation of organic dibasic acid and dihydric alcohol. It is a polymer compound and is the largest variety of synthetic fibers at present. Polyester fabrics are widely used in the luggage customization industry, and polyester fabrics are used in many bag products. Therefore, if you see "polyester fiber" written on the material description of the backpack tag in the future, then the backpack is made of polyester fabric.

Polyester fabric is one of the custom conventional fabrics for backpacks. It has excellent wrinkle resistance, shape retention, high strength and elastic recovery ability, wrinkle resistance, no ironing, non-stick hair and other advantages.

1. The elasticity of polyester fabric is good

Polyester fabric has high strength and elastic recovery ability, and has good wrinkle resistance and shape retention. It is used to make backpacks. The finished backpack is strong and wear-resistant. The fabric is not easily deformed under the action of external force, very wrinkle-resistant, and basically does not need ironing. , the package body layout will be relatively flat, three-dimensional and stylish. Under normal use, backpacks made of polyester fabrics are relatively durable and not easily deformed.

2. Good light resistance

Lightfastness is second only to acrylic (artificial wool). The light fastness of polyester fabric is better than that of acrylic fiber, and its light fastness is better than that of natural fiber fabric. Especially the light fastness behind the glass is very good, almost on par with acrylic. Backpack products made of polyester fabrics are not prone to weathering, embrittlement and fracture when used in outdoor conditions.

3. Poor dyeability

Although polyester fabric has poor dyeability, it has good color fastness. Once dyed successfully, it will not fade easily, and it will not easily fade during the washing process. It is made into a backpack product, and the fabric is not easy to fade after long-term use, and the color retention effect is very good.

4. Poor hygroscopicity

The hygroscopicity of polyester is weaker than that of nylon, so the air permeability is not as good as that of nylon, but it is precisely because of the poor hygroscopicity of polyester fabrics that polyester fabrics are easy to dry after washing, and the fabric strength hardly decreases, so it is not easy to deform. The manufactured backpack products use the correct washing method, and are generally not prone to deformation due to washing.

5. Good thermoplasticity and poor melting resistance

Due to the smooth surface of polyester and the close arrangement of internal molecules, polyester is the fabric with the best heat resistance among synthetic fiber fabrics and has thermoplastic properties. Therefore, polyester fabric backpacks should try to avoid contact with cigarette butts, sparks, etc.

In the weaving process of polyester fabrics, due to the different thicknesses of the fibers used, they can also be divided into different types of specifications. The specifications of polyester fabrics are generally expressed by "fineness (D)", and the fineness is also called denier, that is, denier. The larger the D number, the thicker the texture of the fabric, the greater the gram weight, and the better the wear resistance. For example, 150D, 210D, 300D, 600D, 1000D, 1680D, etc. are commonly used polyester fabric specifications, such as 150D, 210D and other smaller denier fabrics, most of which are used to make backpack linings, 300D and above specifications fabrics, basic It is used as the main material of the backpack.

Post time: Sep-24-2022